At MAAGNITE, we understand that innovation often starts by learning from what already exists. Our Reverse Engineering Modelling services help businesses transform physical products into accurate digital models, unlocking opportunities for improvement, replication, and innovation.

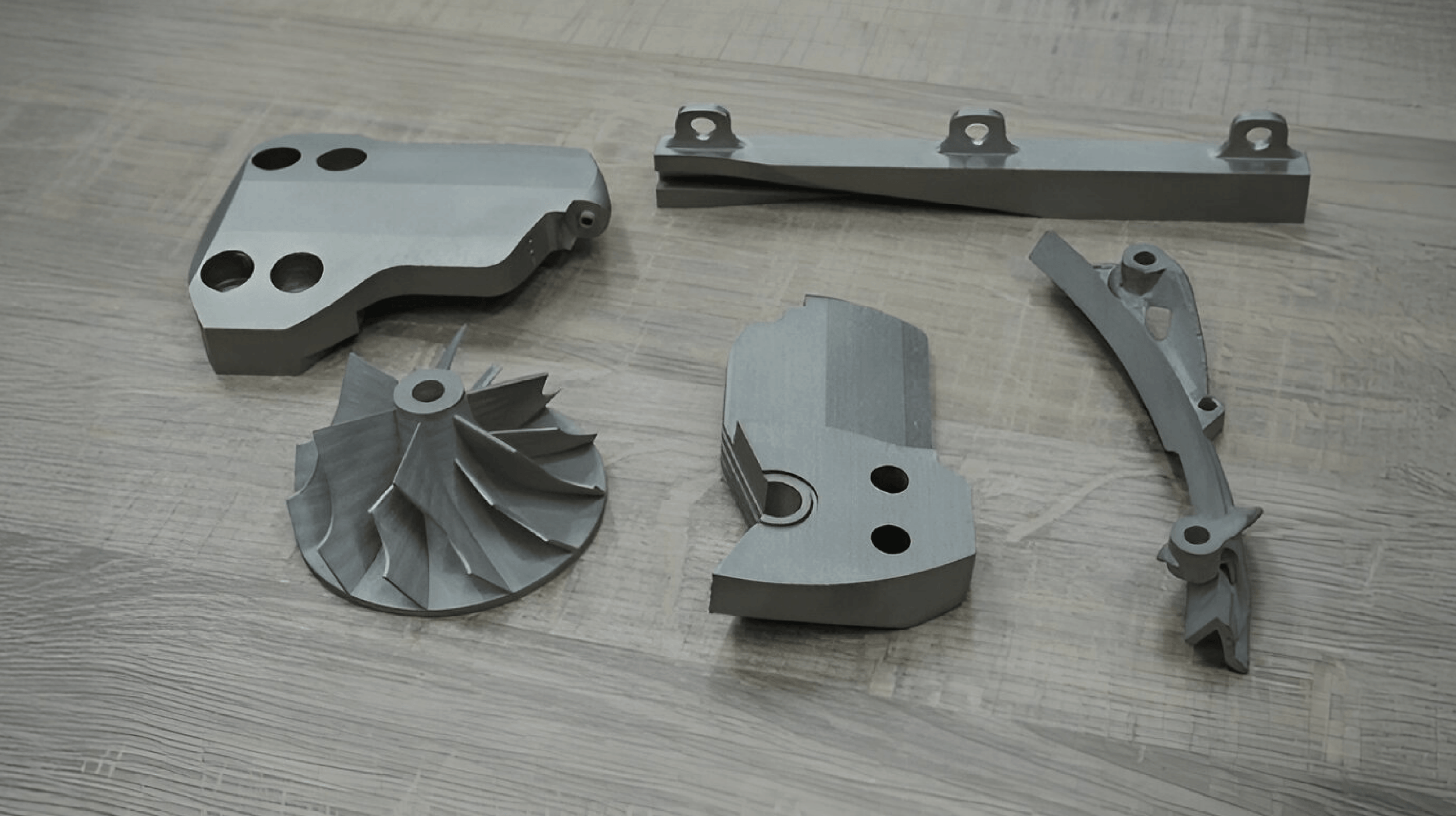

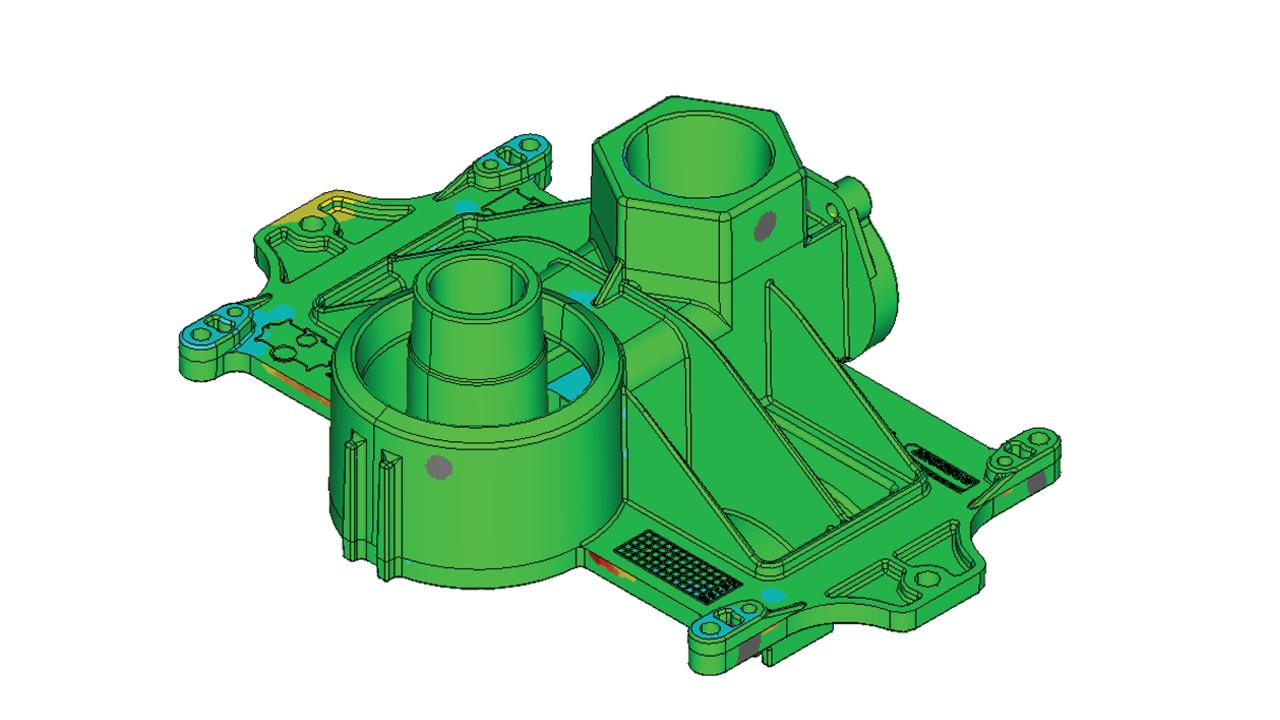

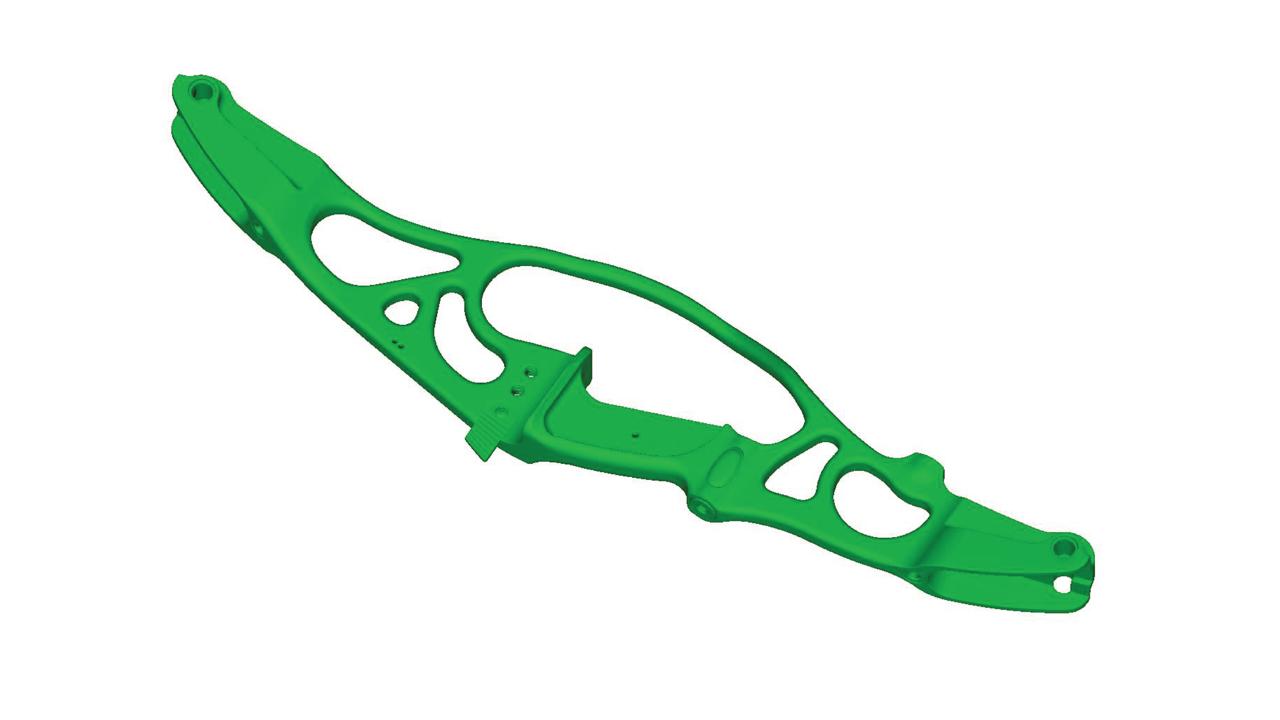

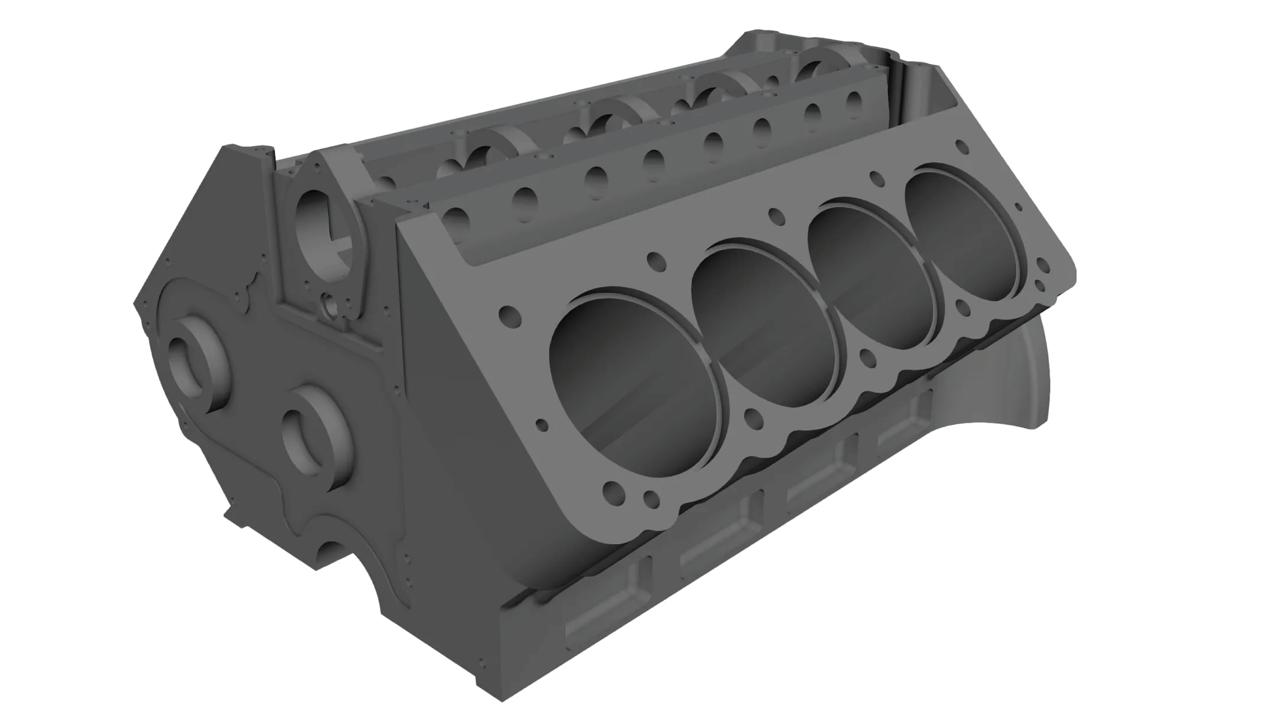

Reverse Engineering Modelling involves analyzing and capturing the exact dimensions, shapes, and functional aspects of a physical object, then recreating it as a detailed 3D CAD model. This process is invaluable for products without original design documentation or for companies looking to optimize and modernize existing designs.

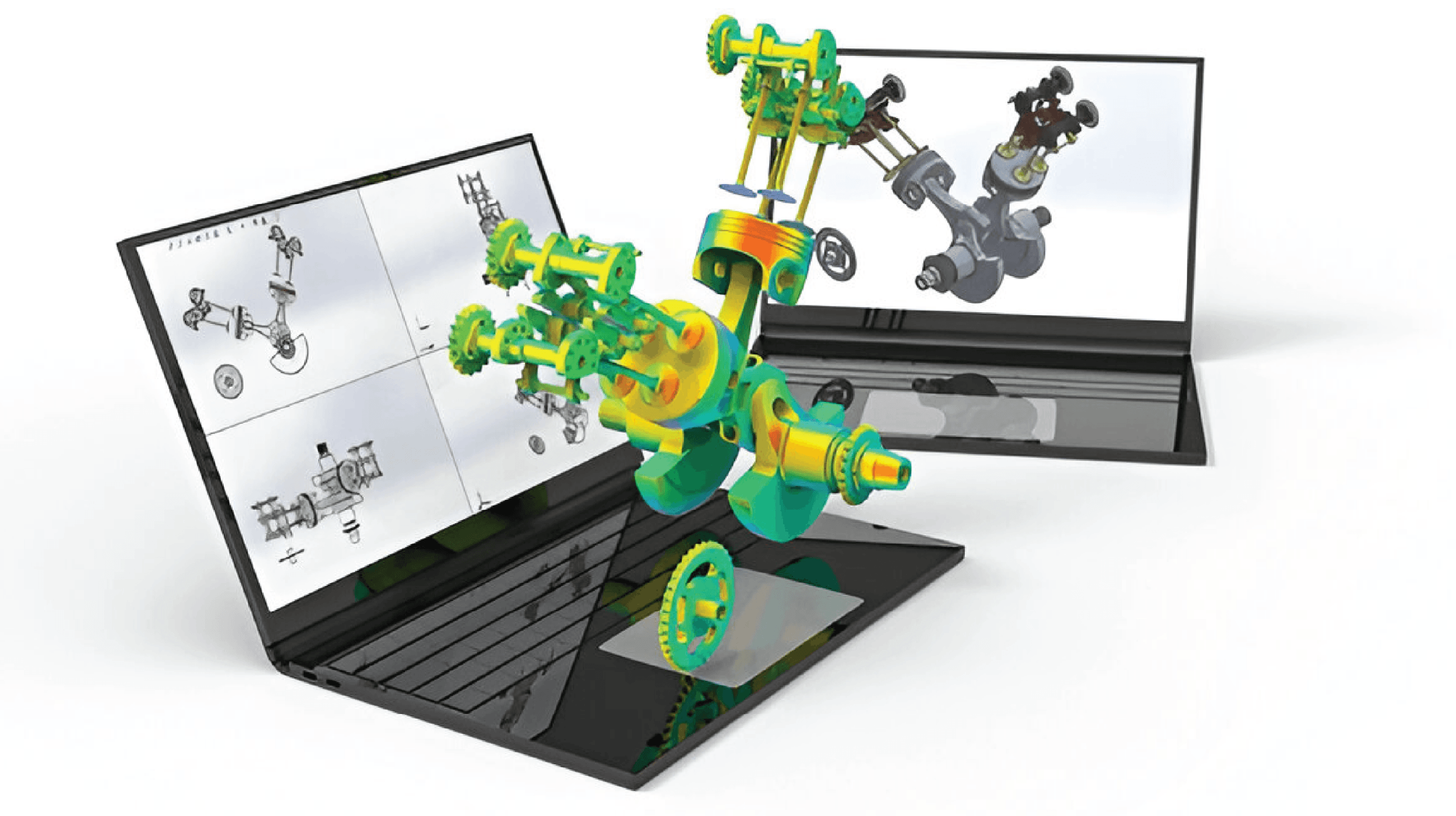

At MAAGNITE, we leverage cutting-edge 3D scanning and reverse engineering tools combined with expert modelling skills to deliver high-fidelity digital replicas. Our models integrate smoothly with your existing CAD systems, enabling you to accelerate design, manufacturing, and quality assurance processes.

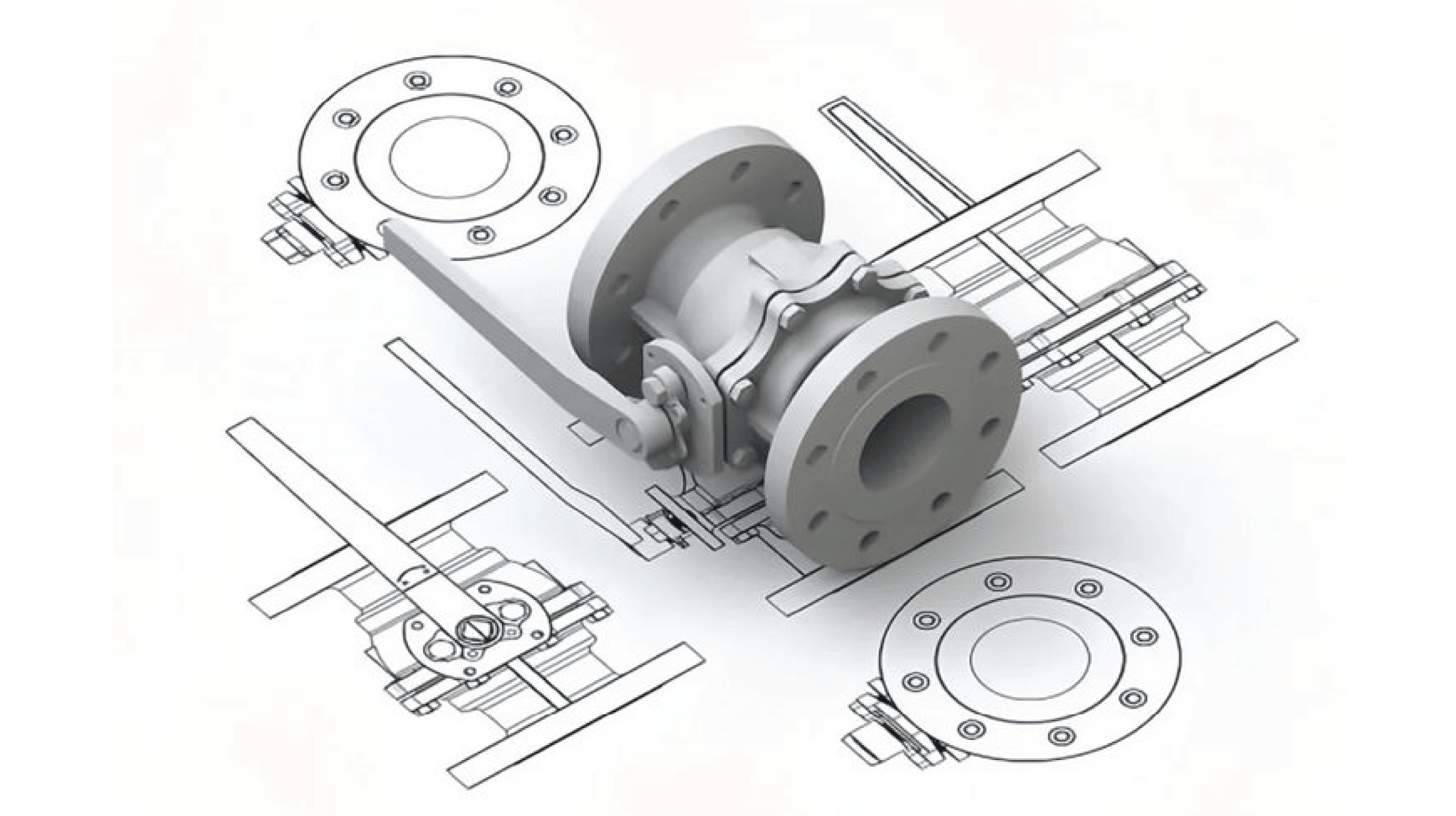

At MAAGNITE, we understand that clear, accurate engineering drawings are the backbone of successful projects. Our engineering drawings service delivers detailed, meticulously crafted technical illustrations that translate complex designs into precise visual documentation. Whether you’re developing new products, constructing facilities, or maintaining critical systems, our drawings ensure seamless communication across teams and stakeholders.

Our drawings go beyond simple sketches; they provide detailed fabrication and erection information, including dimensions, welding details, bolt patterns, material specifications, and cutting instructions. By leveraging advanced CAD and BIM software, we produce shop-ready drawings that minimize errors, reduce waste, and accelerate project timelines.

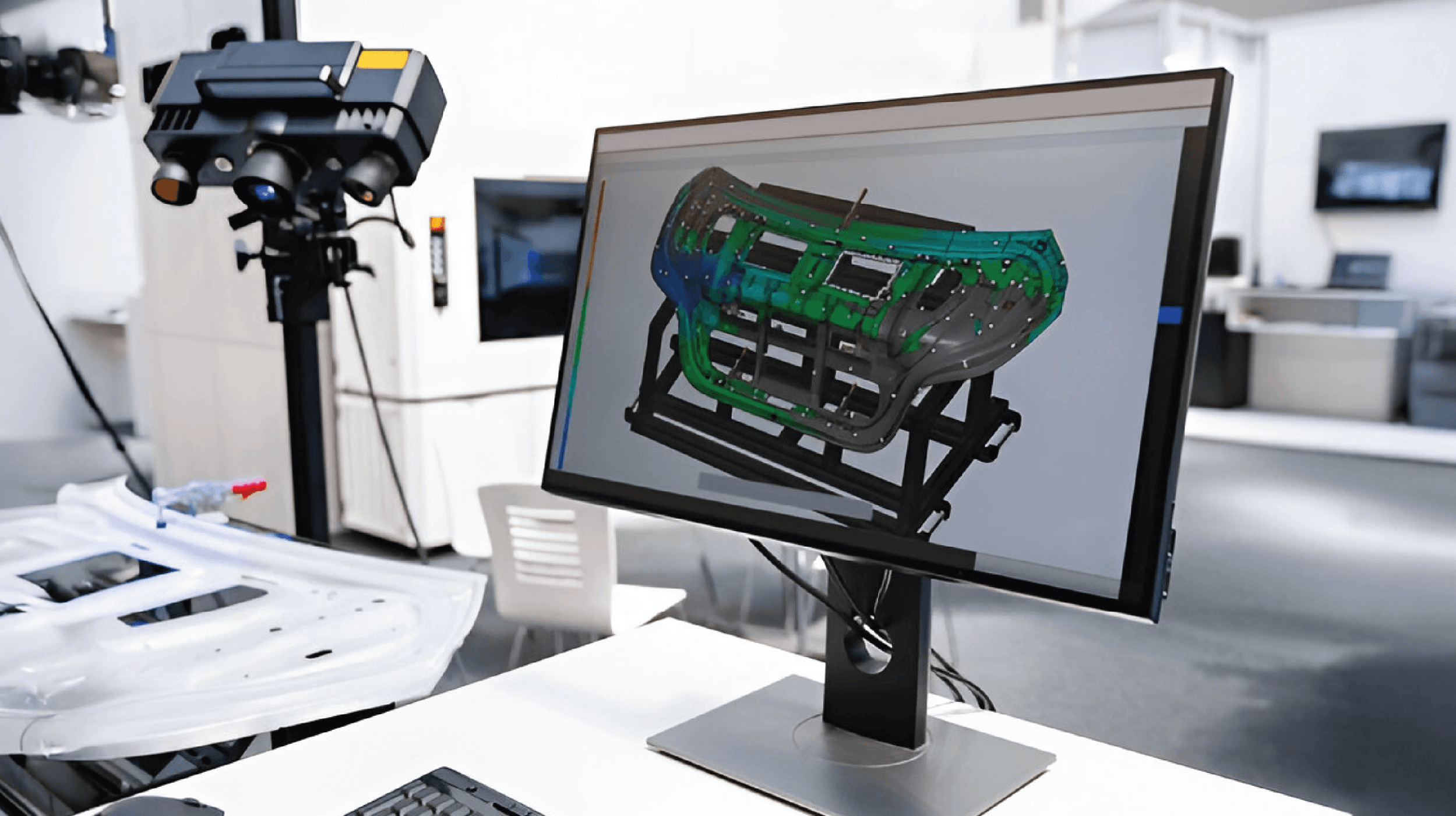

In the dynamic field of reverse engineering, precision and accuracy are paramount. Our Inspection and Deviation Reports serve as critical tools to ensure every stage of the reverse engineering process meets stringent quality standards and client specifications.

An Inspection Report documents the detailed examination of components, parts, or assemblies that are reverse-engineered. It captures measurements, material properties, surface finishes, and other critical attributes compared to the original design or intended specifications. When discrepancies arise between the expected and actual conditions, a Deviation Report highlights these variances, explaining their nature, cause, and potential impact.

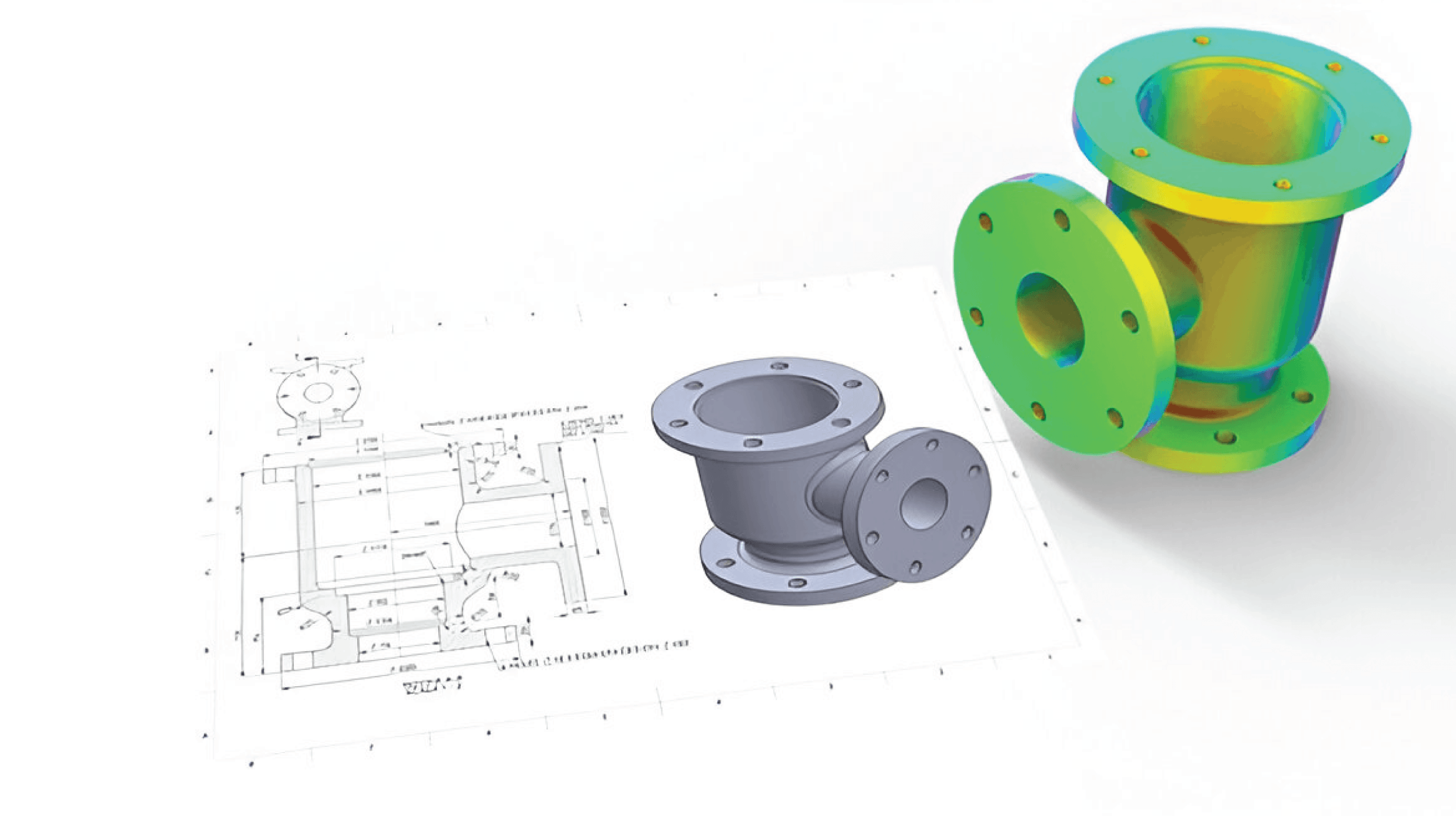

In today’s fast-paced technological landscape, understanding and improving existing products is essential for innovation and competitive advantage. Reverse engineering is the strategic process of deconstructing a product, system, or software to uncover its underlying design, functionality, and components. This approach enables companies to gain valuable insights without starting from scratch.

Unlock Hidden Knowledge: By analyzing existing solutions, we reveal design principles and operational mechanisms that can inspire new ideas or improve current offerings.

Enhance Compatibility: It ensures seamless integration with legacy systems or third-party products, facilitating smoother workflows and greater efficiency.

Support Maintenance and Upgrades: Reverse engineering provides the blueprint needed to maintain, repair, or upgrade products, extending their lifecycle and maximizing investment.

Drive Competitive Analysis: Reverse engineering provides a clear view of competitor products, enabling strategic improvements and differentiation without infringing on intellectual property.